XỬ LÝ NƯỚC BẰNG CÔNG NGHỆ UF

- Mô tả

Mô tả

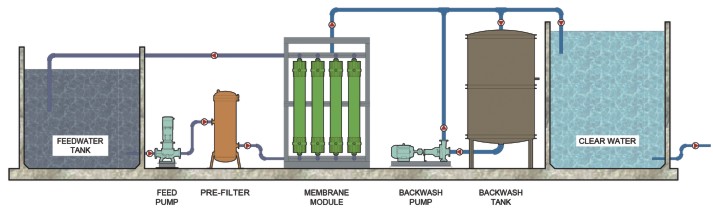

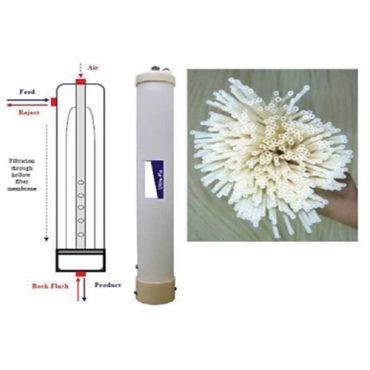

System process

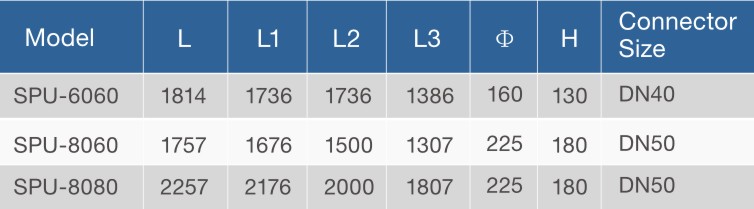

Module dimension(mm)

Specification

| TYPE | 6060 | 8060 | 8080 | |

| Specification | Membrane material | PVDF | ||

| Membrane structure | Outside-to-side | |||

| Nominal pore size | 0.03μm | |||

| Fiber inside/outside diameter | 0.7mm/1.3mm | |||

| Effective membrane area | 35㎡ | 55㎡ | 75㎡ | |

| Dimension | Dimension | ⌀160×1814mm | ⌀225×1757mm | ⌀225×2257mm |

| Inlet/outlet connection | DN40 | DN50 | DN50 | |

| Weight | Wet condition | 42kg | 75kg | 92kg |

| Filtration type | Dead-end/Cross-flow | |||

| Turbidity of permeate water | ≤0.1NTU | |||

| SDI15 | ≤3.0 | |||

Application condition

| Feed condition | Turbidity | ≤300NTU |

| pH | 2-10 | |

| Prefiltration accuracy | 100-300μm | |

| Operating temperature | 1-40℃ | |

| Design flux | 30-120L/㎡·h,25℃ | |

| Max.filtrating trans-membrane pressure | 0.2MPa | |

| Backwash condition | Backwash frequency | 20-60mins/time |

| Backwash max.filtrating trans-membrane pressure |

≤0.2MPa | |

| Backwash flux | 80-120L/㎡·h | |

| Air cleaning condition | Inlet pressure | ≤0.25MPa |

| Air scour flux | 4-10Nm³/h·㎡(projected area) | |

| Chemical Enhanced Backwash | Frequency | Adjust according to water quality or pilot test |

| Cleaning solutions | 0.1%HCl,0.05%NaOH+0.1%NaClO(Adjust according to water quality) | |

| Chemical In Place | Frequency | Filtrating trans-membrane pressure is increased to 0.08-0.1MPa |

| Cleaning solutions | 2%Oxalic acid,1-2%Citric acid or 0.4%HCl acid,0.1%NaOH+0.2%NaClO | |

Feature

1.Seamless repacement

2.Low energy consumption

3.Long lifespan

4.High water quality

5.Prolonged wash cycle

Specification

| Model | Revita RP-8060D | Revita RP-8080D | |

| Specification | Membrane material | PVDF | |

| Active membrane area | 52㎡ | 77㎡ | |

| Nominal pore size | 0.03um | ||

| Inside/outside diameter | 0.7/1.3mm | ||

| Membrane structure | Outside-to-inside hollow fiber | ||

| Dimension | Dimension(L×W×H) | ⌀225*1860mm | ⌀225*2360mm |

| Connector | DN50 | ||

| Material | Shell material | UPVC | |

| Encapsulating material | Epoxy resins/Polyurethane | ||

| Weight | Dry condition | 75kg | 92kg |

Application condition

| Backwash condition | Frequency | Every 20-60mins(According to water quality or pilot testing result) |

| Pressure | ≤0.2Mpa | |

| Flux | 80-120L/㎡·h | |

| Air cleaning condition | Air pressure | ≤0.2Mpa |

| Air scour flux | 4-10Nm³/h·㎡(projected area) | |

| Chemical Enhanced Backwash | Frequency | Every 12-24h(According to water quality or pilot testing result) |

| Cleaning solutions | 0.1%HCI(Adjust according to water quality) | |

| 0.05%NaOH+0.1%NaCIO(Adjust according to water quality) | ||

| Clean In Place | Frequency | TMP exceeds 0.08-0.1Mpa,and the flux cannnot recover from backwash,air scour and Chemical Enhanced Backwash |

| Cleaning solutions | 2% Oxalic,1-2% Citric or 0.4%HCI | |

| 0.1%NaOH+0.2%NaCIO(Active Chlorine) |

Note:

1.The actual permeate and backwash flux depends on system’s operation and maintenance condition.

2.The permeate water quality may varify according to feed water condition.