MÀNG LỌC SINH HỌC ALFA LAVAL CỦA THUỴ ĐIỂN

- Mô tả

Mô tả

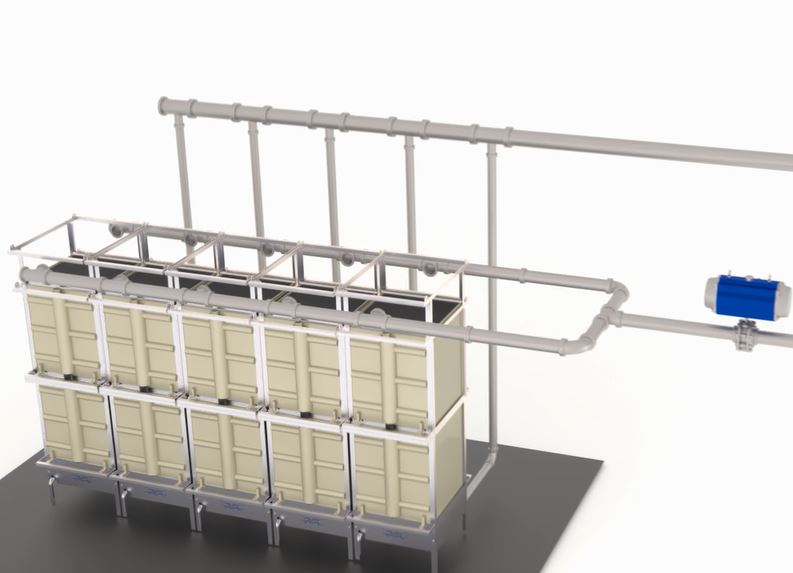

MODEL MÀNG LỌC SINH HỌC ALFA LAVAL CỦA THUỴ ĐIỂN

Màng lọc sinh học Alfa Laval diện tích 129 m2 model MFM 080

Màng lọc sinh học Alfa Laval diện tích 193 m2 model MFM 120

Màng lọc sinh học Alfa Laval diện tích 257 m2 model MFM 160

Màng lọc sinh học Alfa Laval diện tích 322 m2 model MFM 200

Màng lọc sinh học Alfa Laval diện tích 386 m2 model MFM 240

CATALOG:

VIDEO:

MBR membranes – case stories

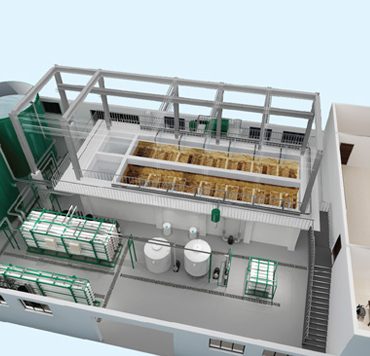

There are over 150 Alfa Laval MBR systems installed across the world, handling all types of municipal and industrial wastewater treatment.

Central Clear Creek uses Alfa Laval MBR membranes

Clear Creek in Denver, Colorado, chooses Alfa Laval’s MBR membranes over conventional activated sludge (CAS) for high quality effluent, reliability, cost savings due to low maintenance requirements, ease of use and more.

Schwander Polska chooses Alfa Laval MBR for low lifecycle costs

The company Schwander Polska designs, builds and operates wastewater plants based on membrane bioreactor(MBR) technology. To ensure long and trouble-free uptime at minimum operating cost, the company has decided to use Alfa Laval MBR membranes in all of their MBR water treatment projects.

Alfa Laval MBR maximizes flexibility and effluent quality at KMC

Potato starch producer KMC processes wastewater with 10,000 mg COD/L in its wastewater treatment plant. Thanks to Alfa Laval’s MBR membranes, the company has the flexibility to use the most suitable bacteria in its membrane bioreactors and can meet the municipality’s demands on effluent quality in wastewater treatment.

How it works

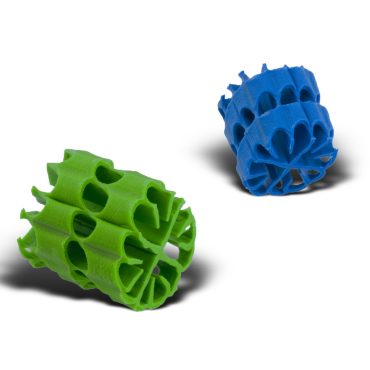

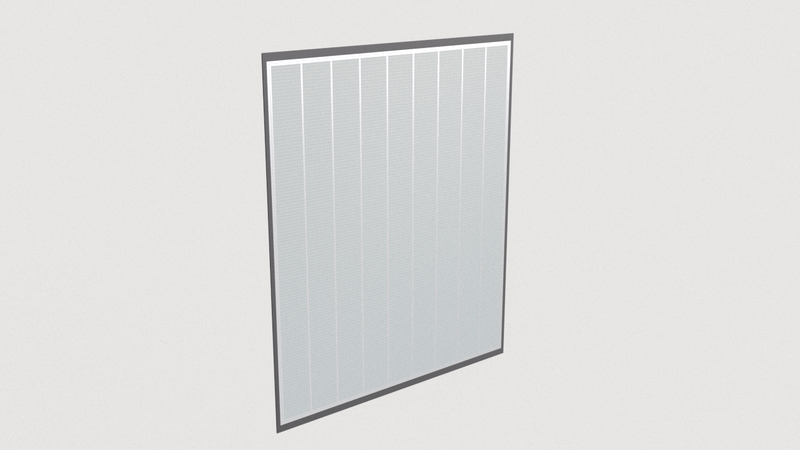

Nature is full of examples of smart, efficient processes, and we have been inspired by a number of them when designing our MBR modules. This has been very successful, resulting in low energy costs, minimal cleaning and high water quality. We gradually develop our MBR module systems to improve them even further, always with the same guiding principle: natural efficiency.

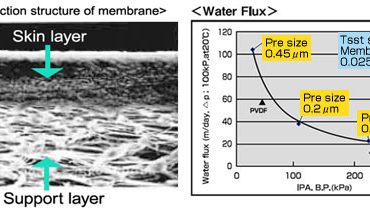

Alfa Laval’s unique LowResist design gives our membrane module an extremely low pressure drop. It is thanks to the ultra-low transmembrane pressure (TMP) that Alfa Laval MBR membranes require much less cleaning and maintenance that other MBRs on the market. The low TMP means there is no pore fouling, just easily removed surface fouling.

It is also the reason Alfa Laval MBR filters can run on gravity with just 1 m of water above the module, making it possible to maximize capacity in a tank without having to use pumps.

In our new model we have improved the LowResist technology to reduce the transmembrane pressure even further. The new membranes have open sides, allowing the water to flow freely into the permeate boxes. This leads to a more even pressure distribution over the membrane, which improves capacity and reduces cleaning needs.

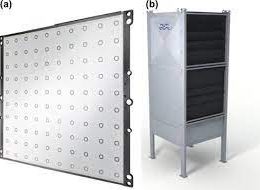

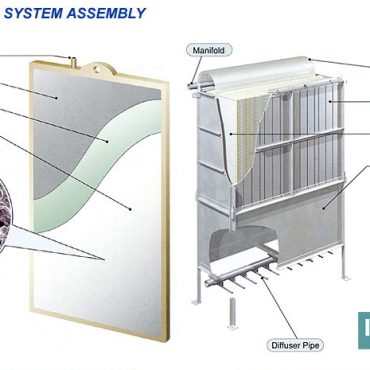

S Aerator™

Our latest MBR model features the S Aerator aeration system. This new, improved system minimizes air consumption during the wastewater filtration process.

Alfa Laval’s new S Aerator uses a single-line design, combined with a flush line.

The design makes it easy to turn the air on and off during operation and allows you to run your MBR membrane modules with alternating aeration. This means that in systems with more than one membrane module, air scouring is applied in an alternating manner, not continuously. This is possible without fouling becoming a problem thanks to the extremely low TMP. The big benefit is savings in energy, investment and maintenance costs.

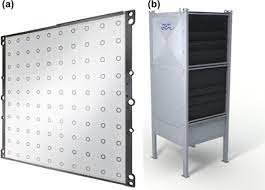

QuickSwap™

MBR membranes are easily installed and replaced thanks to Alfa Laval’s unique QuickSwap™ technology. Alfa Laval’s unique QuickSwap™ technology means each pack can be removed individually, minimizing the lifting height required above the membrane module. This means that Alfa Laval’s MBR membrane modules are especially suitable for indoor or subterranean installations where extra lifting height means more capital cost.

Membranes are easily replaced thanks to the QuickSwap™ technology. With all of the membranes in a module mounted in packs, an entire pack can be replaced in one operation, instead of having to replace each membrane element individually.

To replace a pack, just lower the tank level, take out the old pack and put in a new one. There is no need to take the entire module out of the tank or spend time ensuring each membrane element is in place after replacing the membranes.

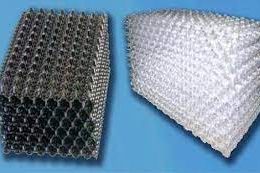

MBR membranes optimized for high capacity

The new Alfa Laval MBR membrane modules only require two free sides during operation and can therefore be installed side by side in rows, thereby increasing the installed membrane density dramatically.

The range of different module sizes in combination with the low water depth required for gravity operation makes it possible to optimize usage of existing tanks and maximize the installed membrane area. With Alfa Laval’s solution you get the most membrane area per tank volume.

The high resistance to fouling and absence of pore fouling in an Alfa Laval MBR membrane makes it possible to operate the bioreactor with up to 50% higher concentrations of suspended solids than other manufacturers’ filters.

Combining these factors means you get maximum capacity per tank volume with Alfa Laval MBR membranes.

MBR Membranes ─ designed for wastewater filtration applications

The membranes are a key part of a MBR wastewater treatment plant and in the treatment of industrial wastewater. We develop and manufacture all membranes used in our MBR modules ourselves to ensure the highest quality and best durability. The membranes are made of chlorine resistant PVDF and have been specifically optimized for use in wastewater applications.

The membranes provide an absolute barrier to bacteria, microplastics and several other pollutants, and the treated water is guaranteed to meet the requirements for water reuse or environmentally responsible discharge.

Fully automated for low personnel requirements

Alfa Laval MBR membranes are easy to operate and can be fully automated. All important aspects, such as air scouring, cycle lengths and CIP can be initiated, controlled and monitored remotely. The only required manual work during the MBR water treatment with our modules is making sure the cleaning chemical tanks are filled.

The resulting personnel requirements are thus very low, normally around 1/4 full-time operator equivalent per plant.

Cleaning

The ultra-low transmembrane pressure and absence of pore fouling means very little cleaning is needed. During normal operation it is enough with a 2 minute relaxation period every 10 minutes for the scouring air to remove the surface fouling.

There is no need for frequent backflushing or chemically enhanced backwashing – only a one to two hour CIP cleaning every two or three months. The time savings compared to other MBR systems are very large.

The long CIP cleaning cycles also brings the benefits of minimizing wear on the membranes and chemical usage.

Benefits of membrane bioreactor filtration

The new version of our membrane bioreactor filtration modules features a number of improvements that increase capacity, cut energy consumption and reduce maintenance costs even further.

Excellent water quality with a membrane bioreactor

One of the biggest advantages with a membrane bioreactor is the outstanding water quality of the effluent. With regulatory demands becoming stricter and stricter, you can rest assured that you have a future-proof solution when you invest in MBR membrane modules from Alfa Laval.

The membrane is an absolute, physical barrier that removes all bacteria and a number of other pathogens, as well as all microplastics, making it suitable for a number of beneficial re-use applications, for example irrigation.

An MBR system is also a great solution for removing compounds of emerging concern, micropollutants and pharmaceuticals from municipal and hospital wastewater.

Alfa Laval MBR membranes are California Title 22-accredited and have been proven totally effective in removing microplastic pollutants in recent studies of a wastewater treatment plant in Denmark. Therefore, you can be sure to meet your future operational needs and those of your local environment.

MBR membranes – low energy costs

Energy is the main cost of operating an MBR plant, making energy efficiency a primary concern. Alfa Laval MBR membranes offer market-leading performance at the lowest possible energy cost.

The unique LowResist™ design of our MBR membranes makes it possible to operate them using gravity as the only driving force, eliminating costs for pumping power.

Alfa Laval’s new S Aerator™ lets you optimize air scouring, and in turn the energy consumption for the air blower, without risking increased blockages in the aerator or increased membrane fouling.

Minimal cleaning of the membrane module

The ultra-low trans-membrane pressure (TMP) that is the foundation of the LowResist membrane module technology minimizes fouling and in turn cleaning needs. The low TMP eliminates pore fouling which means the only cleaning an Alfa Laval MBR filter ever needs is relaxation/air scouring every 10 minutes and CIP 4-6 times per year.

In other words:

- No backflushing

- Low requirements for chemical backwash and no soakings in most cases

- No need to ever remove the filter module from the tank during its lifetime

- Minimal CIP

- Minimal use of chemicals

- Huge time savings

- Less wear and tear on membranes and pumps

Easy, reliable operation

Every detail of an Alfa Laval MBR membrane system, has been designed and manufactured specifically for use in wastewater applications. There are no moving parts or valves in the sludge, and pump usage has been minimized. Nothing has been left to chance to secure maximum reliability and the lowest possible maintenance requirements.

There is no maintenance that will ever require you to remove the filter module from the bioreactor tank or to empty it. In case you need to replace a membrane, our unique QuickSwap system lets you do this in record time in the membrane tank.

No advanced training for your personnel is required if you are revamping an existing wastewater treatment plant to MBR technology. All the technologies in our system will be familiar to your staff.