Giá thể vi sinh dạng cầu MBBR của AGAR

- Mô tả

Mô tả

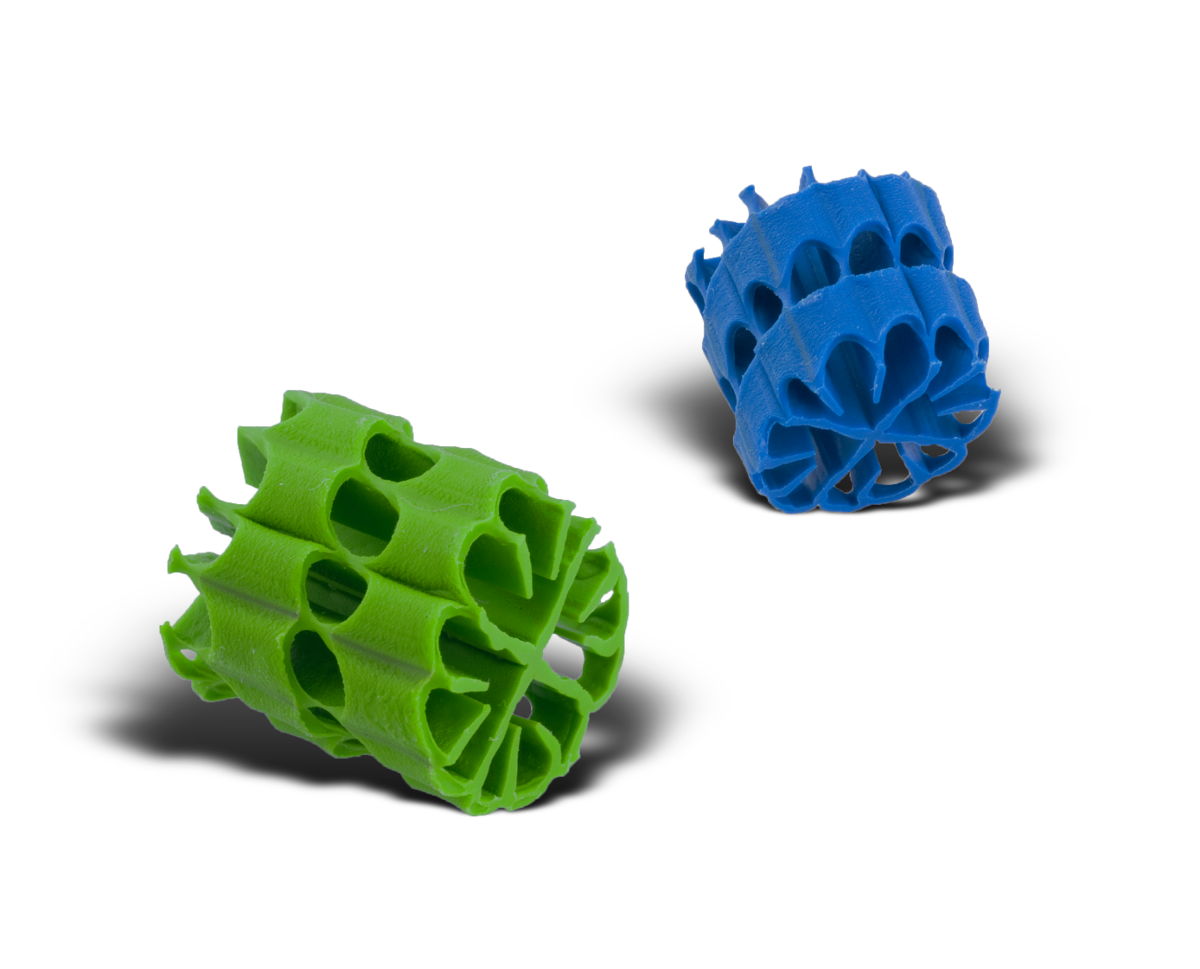

GIÁ THỂ VI SINH DẠNG CẦUKích thước: D100

Khả năng chịu nhiệt: 50-80 độ C

Diện tích bề mặt: 250-350 m2/m3

Vật liệu chế tạo: PP/PVC

Số quả cầu/m3: 600 quả

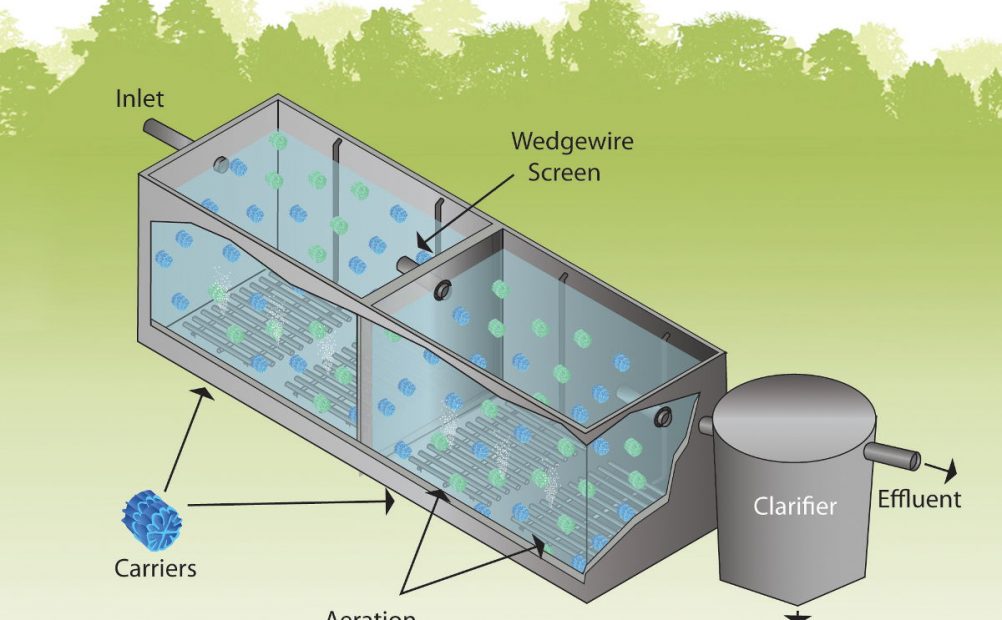

It combines Aqwise’s ABC carriers with highly efficient aeration and mixing system, moving the carriers in a double roll motion.

The AGAR® MBBR eliminates the need to recycle sludge from a secondary clarifier and can be divided into multiple stages thus increasing the removal rate and reduces footprint. The solution can be applied for both high load industrial and municipal applications.

Features

- Strong and efficient biological process – high removal rates

- Up to 50% smaller footprint

- Less air requirement

- COD/BOD/Nitrogen removal.

- Usage of fine or coarse bubbles diffusers for aeration

- No need to recycle sludge back to the reactor

- Carbon recovery is part of the process

- High removal rates compared to alternative systems such as activated sludge and SBR

- Superior self-cleaning of the carriers and screens

Benefits

- Low operational expenses – energy savings up to 30% compared to other MBBR processes

- Simple operation

- Can be used to retrofit existing plants in existing tanks & reactors

- Minimal biological clogging on the carriers and media screens

- Fast recovery

How does the AGAR® MBBR process work?

The AGAR® MBBR technology uses the grown biofilm on the carriers and aeration system to perform an effective biological wastewater treatment.

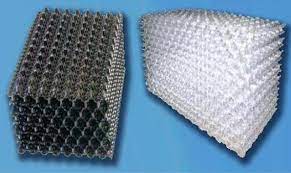

Wastewater is introduced into a single or multi-stage system with ABC carriers according to the required effluent quality. Air is supplied via fine/coarse bubble diffusers located at the bottom of the reactor.

The unique “double roll” aeration design can be implemented with either coarse or fine bubble diffusers and creates constant collisions between the carriers to keep a thin biofilm layer. In most cases, the amount of air needed for biological activity is sufficient to maintain the roll pattern, thus no additional air expenses are required for mixing. The use of fine bubble diffusers allows better energy efficiency and is unique to the AGAR®.

Stainless steel screens are installed at the outlet of each biological stage to keep the carriers inside the reactor, whilst allowing the flow of mixed liquor out. The screens are continuously cleaned by the biomass carriers to prevent clogging.

The effluent exits the reactor to a solid-liquid separation unit such as clarifier, DAF, Media-Clarifier, etc. For nitrogen removal, an MBBR-BNR (Biological Nutrient Removal) will be applied. The process includes both aerobic and anoxic reactors for nitrification and de-nitrification in a multi-stage system.